Unit-2

Storage and distribution of water

Q1) What are the various requirements of the good distribution system?

A1)

Various requirements for proper functioning of a distribution system as

● It should be capable of supplying water at all the intended places within the city with the reasonably sufficient pressure head.

● Capable of supplying required amount of water for fire fighting.

● Cheap with least capital construction cost (70% cost of total cost).

● Simple and easy to operate and repair.

● Safe against any future pollution of water (away from sewerage lines).

● Safe so as not to cause failure of pipeline by busting.

● Must be water tight so as to keep ‘losses due to leakage’ to minimum.

Q2) Explain the layout of distribution network in brief.

A2)

Four types, any of which singly or in combination can be used depending on local condition and orientation of roads.

1. Dead end system

It is also called tree system. When main supply pipe, from which, at right angles, originates and number of sub main pipes. Sub main divide into branch pipes or literals from which service connections are given to consumers.

Adopted for old town that is unplanned. A number of dead ends are formed.

Advantages

a) Distribution network can be solved easily and we can easily calculate the discharge and pressure at different points.

b) Less number of sluice valves are cut off valves are required.

c) Shorter pipe lengths are needed and lying of pipes is easy.

d) Cheap and simple, can be extended or expanded easily.

Disadvantages

a) Only one route so any damage in pipe will completely stop water supply.

b) Numerous dead ends are there which prevents free circulation of water which may degrade its quality. This state of water has to be removed preorder cli by providing scour valves.

c) Supplies during fire fighting cannot be increased.

2. Grid iron system

It is also known as interlaced system or reticulation system. The mains, sub mains and branches are interconnected full stop suitable for well planned town and cities. It is used in Chandigarh.

Advantages

a) Since water reaches at different places through more than one route, the discharge to be carried by each pipe, the friction loss and size of the pipe get reduced.

b) For repair, very small area will be devoid of complete supply.

c) Because of different interconnections, the dead ends are eliminated.

d) During fire, more water can be diverted towards affected point.

Disadvantages

a) This system requires more length of pipe line and large number of sluice valve and cut-off valve and gate valve.

b) Construction is costlier.

c) Design is difficult and costly year. Calculation for sizes of pipe and pressure at key points required design experts.

3. Ring system

Also called circular system full stop a closed ring either circular or rectangular off main pipes is formed around the area to be served. Distribution area is divided into rectangular or circular blocks. It is suitable for town and cities.

Sometimes it is used as looped feeder placed centrally around the high demand area along with grid iron system.

Advantages and disadvantages are same as grid iron system.

4. Radial system

If a city has system of radial roads emerging from different centers, the pipelines are laid in radial method by placing distribution reserve wires at these corners. Here, water is taken from mains, supplied by a radially laid distribution pipes.

Q3) What are the various disadvantages of the intermittent system?

A3)

a) In many cities the intermittent system may fail to give any savings.

b) They do not cover fire risk during non supply periods.

c) Inconvenience to consumers.

d) Require bigger size distribution means for 6 to 8 hour supply as water is supplied to whole town at same time.

e) When supply is stopped and water is drawn off, a partial vacuum may be created in pipe which induces section through leaky joints so as that dirt may enters to the pipe.

f) More air valves and sluice valves are required which will have to be operated daily requiring more ward staff and maintenance cost.

Q4) What are the various functions of distribution reservoirs?

A4)

Q5) What is the concept of balancing storage or equalizing storage?

A5)

Main function of reserve wire is to meet fluctuating demand with constant date of supply from treatment plant. The quantity of water required to be stored in reserve wire for equalizing for balancing this variable demand against constant supply is known as balancing reservoir or balancing storage or the storage capacity of a balancing reservoir. This is calculated by utilizing hydrographs of inflow and outflow by following two methods:

Mass curve method

It is also called mass diagram method and it is the plot of accumulated in flow that is supply outflow that is demand v/s time. The mass curve of supply is first drawn and is superimposed by demand curve. The amount of balancing storage can be determined by adding the maximum ordinates between demand and supply lines.

Steps: -

Analytical solution

The cumulative hourly demand and cumulative hourly supply are tabulated for 24 hours. The early access of demand and supply are then work doubt. The submission of maximum of excess of demand and supply will give required storage capacity.

Q6) What is the factor that affects the location and height of distribution reservoir?

A6)

a) They must be located in heart of city so as to command the maximum area on around and place near points of heaviest demand.

b) Must be located at higher elevation to maintain advocate pressure in distribution system.

c) With respect to position of pumping stations and distribution area, the reservoirs may be located in two different ways i.e.,

Q7) What are the general design guidelines for distribution system?

A7)

Depending upon various factors such as relative levels of the different zones of the city, the layout of the roads etc, the type of distribution network is decided.

1. Fixing the size of pipes of simple distribution system

After the layout plan of distribution system pipes and location of other appurtenances (Valves, hydrants) is finalized, the sizes of the pipes are computed. The terminal pressure in pipes must remain above the minimum allowable pressure and not exceed maximum allowable pressure.

V = 0.85 CH R0.63 S0.54

S =

HL =  1.85

1.85

2. Analysis of complex pipe networks

In a pipe network, the following two conditions must be satisfied: -

a) The algebraic sum of the pressure drops around a closed loop must be zero that is there can be no discontinuity in the pressure.

b) The slow entering a junction must be equal to the floor living the same junction that is the law of continuity must be satisfied.

c) Based on the principle, the pipe networks are solved by the following methods of successive approximation as analytical solution is not possible

3. Hardy cross method

The procedure suggested by hardy and cross requires that the flow in each pipe is assumed by designer in magnitude as well as in direction in such a way that the principle of continuity is satisfied at a junction (i.e., the inflow at any junction becomes equal to the outflow at that junction).

A connection to these as wind flow is then computed successively for each pipe loop in the network, until the correction is reduced to an acceptable magnitude.

Qa = Assumed Flow, Q = Actual flow in the pipe

Now, expressing the head loss (HL) as

HL=K.Qx

We have the head loss in a pipe

=K. [Qax + x.Qax-1 + .........negligible terms]

=K. [Qax + x.Qax-1]

Now, around a closed loop, the summation of head losses must be zero.

K. [Qax + x.Qax-1] = 0

K.Qax = -Kx Qax-1

Since, d is the same for all the pipes of the considered loop, it can be taken out of the summation.

Or, K.Qax = -Kx Qax-1

Or, =-K.Qax/ x.KQax-1

Since d is given the same sign (direction) in all pipes of the loop, the denominator of the above equation is taken as the absolute sum of the individual items in the summation. Hence,

Where HL is the head loss for assumed flow Qa.

The numerator in the above equation is the algebraic sum of the head losses in the various pipes of the closed loop computed with assumed flow. Since the direction and magnitude of flow in these pipes is already assumed, their respective head losses with due regard to sign can be easily calculated after assuming their diameters. The absolute sum of respective KQax-1 or HL/Qa is then calculated. Finally the value of d is found out for each loop, and the assumed flows are corrected. Repeated adjustments are made until the desired accuracy is obtained.

The value of x in Hardy- Cross method is assumed to be constant (i.e. 1.85 for Hazen-William's formula, and 2 for Darcy-Weisbach formula)

Steps

K.Qa2

4. Apply the corrections obtained to the floors in each pipe. Pipes common to two loops will receive both corrections with due regard to sign.

4. Equivalent pipe method

It is used for large network of pipes where it is convenient to replace the different small loops by a single equivalent pipe having same discharging capacities and causing same head loss.

Same discharging capacities and causing same head loss.

It is also called head balanced method of analyzing water distribution five networks.

The pipe net circuit can be reduced into a single equivalent pipe by using two principle of hydraulics: -

a) The loss of head caused by a given flow of water through the pipe is connected in series is additive.

b) The quantity of discharge flowing through the different pipes connected in parallel will be such as to cause equal head loss through each pipe.

5. Other methods

Electrical analyzer method, the method of sections, the circle method, the pitotmeter distribution studies method etc. are also used but they are not of much utility and rarely used.

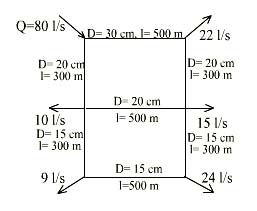

Q8) Calculate the head losses and the corrected flows in the various pipes of a distribution network as shown in figure. The diameters and the lengths of the pipes used are given against each pipe. Compute corrected flows after one correction.

A8)

First of all, the magnitudes as well as the directions of the possible flows in each pipe are assumed keeping in consideration the law of continuity at each junction. The two closed loops, ABCD and CDEF are then analyzed by Hardy Cross method as per tables 1 & 2 respectively, and the corrected flows are computed.

Consider loop ABCD

Pipe | Assumed flow | Dia of pipe | Length of pipe (m) | K = L | Qa1.85 | HL= K.Qa1.85 | lHL/Qal | ||

| in l/sec | in cumecs | d in m | d4.87 | |||||

(1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

AB BC CD DA | (+) 43 (+) 23 (-) 20 (-) 35 | +0.043 +0.023 -0.020 -0.035 | 0.30 0.20 0.20 0.20 | 2.85 X10-3 3.95 X10-4 3.95 X10-4 3.95 X10-4 | 500 300 500 300 | 373 1615 2690 1615 | 3 X10-3 9.4 X10-4 7.2 X10-4 2 X10-3 | +1.12 +1.52 -1.94 -3.23 | 26 66 97 92 |

S |

|

|

|

|

|

|

| -2.53 | 281 |

HL= (Qa1.85L)/ (0.094 x 100 1.85 X d4.87)

or K.Qa1.85= (Qa1.85L)/ (470 X d4.87)

or K =(L)/ (470 X d4.87)

For loop ABCD, we have d =-SHL / x.S lHL/Qal

= (-) -2.53/ (1.85 X 281) cumecs

= (-) (-2.53 X 1000) / (1.85 X 281) l/s

=4.86 l/s =5 l/s (say)

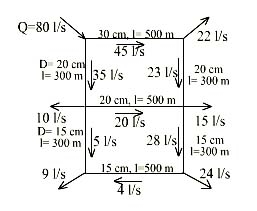

Hence, corrected flows after first correction are:

Pipe | AB | BC | CD | DA |

Corrected flows after first correction in l/s | + 48 | + 28 | - 15 | - 30 |

Consider loop DCFE

Pipe | Assumed flow | Dia of pipe | Length of pipe (m) | K = L | Qa1.85 | HL= K.Qa1.85 | lHL/Qal | ||

| in l/sec | in cumecs | d in m | d4.87 | |||||

(1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

DC CF FE ED | (+) 20 (+) 28 (-) 8 (-) 5 | +0.020 +0.028 -0.008 -0.005 | 0.20 0.15 0.15 0.15 | 3.95 X10-4 9.7 X10-5 9.7 X10-5 9.7 X10-5 | 500 300 500 300 | 2690 6580 10940 6580 | 7.2 X10-4 1.34 X10-3 1.34 X10-4 5.6 X10-5 | +1.94 +8.80 -1.47 -0.37 | 97 314 184 74 |

S |

|

|

|

|

|

|

| +8.9 | 669 |

For loop ABCD, we have d =-SHL / x.S lHL/Qal

= (-) +8.9/ (1.85 X 669) cumecs

= (-) (+8.9 X 1000)/ (1.85 X 669)) l/s

= -7.2 l/s

Hence, corrected flows after first correction are:

Pipe | DC | CF | FE | ED |

Corrected flows after first correction in l/s | + 12.8 | + 20.8 | - 15.2 | - 12.2 |

Q9) Explain elevated reservoirs.

A9)

It may be rectangular circular or elliptical overhead tanks erected at contain suitable elevation above ground level and supported on towers.

Accessories are

a) Inlet pipe for entry of water.

b) Outlet pipe connected to distribution mains for exit of water.

c) Overflow pipe discharging into drain cutter and maintaining constant level.

d) Afloat gauge or indicator for maintaining indicating the depth of water that can be read from outside.

e) A washout pipe and drain pipe for removing water after reservoir cleaning.

f) Automatic device to stop pumping when tank is full.

g) Letters to reach top of reservoirs and up to bottom for inspection.

h) Manholes for providing entry into tank for inspection.

i) Ventilators for fresh air circulation.

Q10) What are the various arrangements of distribution pipes and other accessories?

A10)

Distribution pipe system consists of supply mains, sub mains, branches and laterals, usually made of cast iron and jointed by spigot and socket joints.

Service connections are made of galvanized cast iron pipes.

The distribution pipes are bid on one side of the roads and streets, usually below footpaths and at about 2 m above and 3 m away from C were so as to avoid future contamination.